Program Management

• Masterplan preparation

• Dedicated engineering team setup

• PMS usage – Gate Review with customer

• Close work with Customer’s

• Production and manufacturing engineering

• Represent customer in front of OEM and Tier 1

• Detail reporting for monitoring Launch Readiness

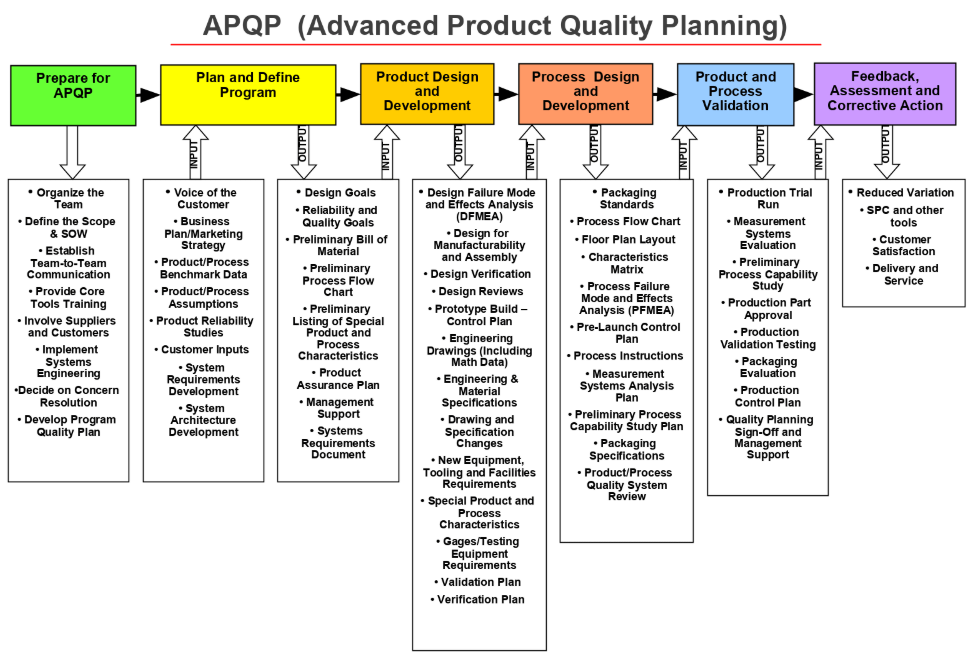

Introduction to Advanced Product Quality Planning (APQP)

Complex products and supply chains present plenty of possibilities for failure,

especially when new products are being launched. Advanced Product Quality

Planning (APQP) is a structured process aimed at ensuring customer satisfaction

with new products or processes.

APQP has existed for decades in many forms and practices. Originally referred to

as Advanced Quality Planning (AQP), APQP is used by progressive companies to

assure quality and performance through planning. Ford Motor Company published

the first Advanced Quality Planning handbook for suppliers in the early 1980’s.

APQP helped Ford suppliers develop appropriate prevention and detection controls

for new products supporting the corporate quality effort. With lessons learned

from Ford AQP, the North American Automotive OEM’s collectively created the APQP

process in 1994 and then later updated in 2008. APQP is intended to aggregate

the common planning activities all automotive OEM’s require into one process.

Suppliers utilize APQP to bring new products and processes to successful

validation and drive continuous improvement.

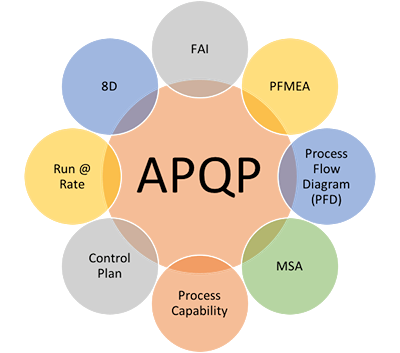

There are numerous tools and techniques described within APQP. Each tool has

potential value when applied in the correct timing. Tools that have the greatest

impact on product and process success are called the Core Tools. The Core Tools

are expected to be used for compliance to IATF 16949. There are five basic Core

Tools detailed in separate guideline handbooks, including Advanced Product

Quality Planning (APQP). The other Core Tools are:

Failure Mode and Effects Analysis (FMEA)

Measurement Systems Analysis (MSA)

Statistical Process Control (SPC)

Production Part Approval Process (PPAP)

English

English Türkçe

Türkçe Deutsch

Deutsch